Advantages and Disadvantages of Domestic vs. Overseas Manufacturing and Suppliers

The supply chain got a reality check during the coronavirus lockdown as ports clogged, shipping costs skyrocketed, and materials became scarce. Being "Made in the USA" became a plus again when it came to reliability. Even though our supply chain woes have lessened, it's time to rethink what and how we offshore supplies and manufacturing for retail displays.

IDD has included plastic fabrication in its business for over three decades. We've built relationships with suppliers across North America to ensure we have acrylic and other materials to make retail displays. We've seen firsthand the realities of offshore competition and have learned to value more than a low price. Creativity is key when a component part, like a hinge, is in short supply. Having partners that can fabricate those components on demand can make or break a display project.

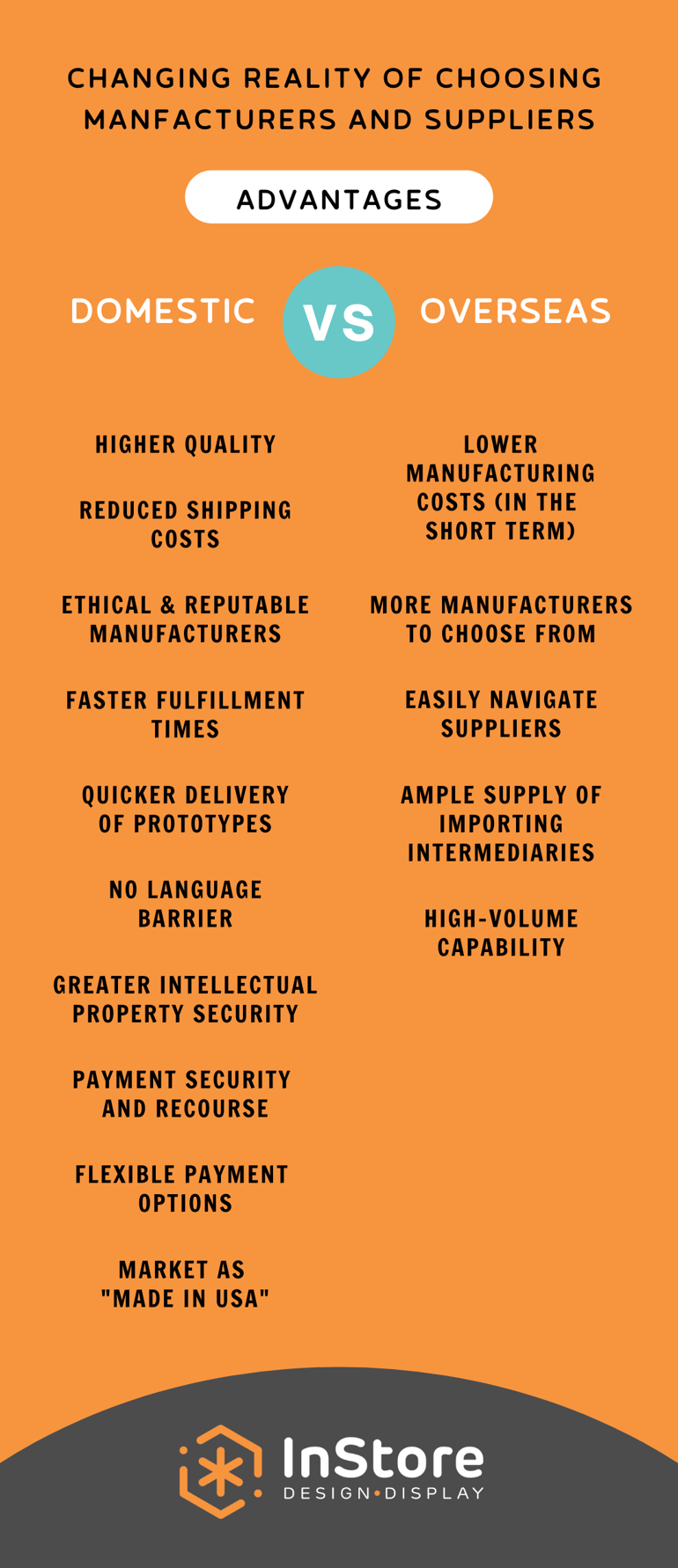

In our review of domestic and overseas sourcing, we've developed the following list as a guide for sourcing the design and build of retail displays and store fixtures.

Still unsure of what's best for your display or store fixture project? Consider these tips on when to go offshore and onshore.

When to Offshore:

- Cost is your primary decision criteria.

- The product you need is not available domestically.

- You have plenty of time to deal with long lead times and delays due to supply chain uncertainty.

- You have a standard product (commodity) where the quality can be checked and controlled by representatives overseas.

- You have time to deal with any quality issues that surface after the product has shipped.

- You don't need to collaborate with the supplier.

When to Onshore:

- You need a collaborative partner working with you through all phases of design development and production.

- The product is complex and clear and effective communication is required.

- You need your product sooner rather than later.

- You have a must-hit deadline.

- Quantities are large or small.

- You need support or questions answered.

- A trusted partner is desired.

When to Use a Hybrid Solution (combination of Onshore and Offshore):

- When you need large quantities, but not all at once, the hybrid solution may be your best bet. It's possible to split an order into domestic and offshore by sourcing the short-term need domestically and the long-term need offshore. The blended cost will be lower and your timelines can be met. If supply chain lead times grow offshore, you can continue to source domestically until the offshore products arrive.

There are certainly times when sourcing materials and products offshore is the best route, but there are many reasons today that put U.S. manufacturers and suppliers in a more favorable position for retail fixtures and displays.

Going with the cheapest option is no longer the competitive advantage it was in the past. Now it's about who can deliver the most value for the brand and the product within the needed time frame and at a competitive price.

Subscribe Here

Stay up-to-date on what's happening on our podcast and blog.