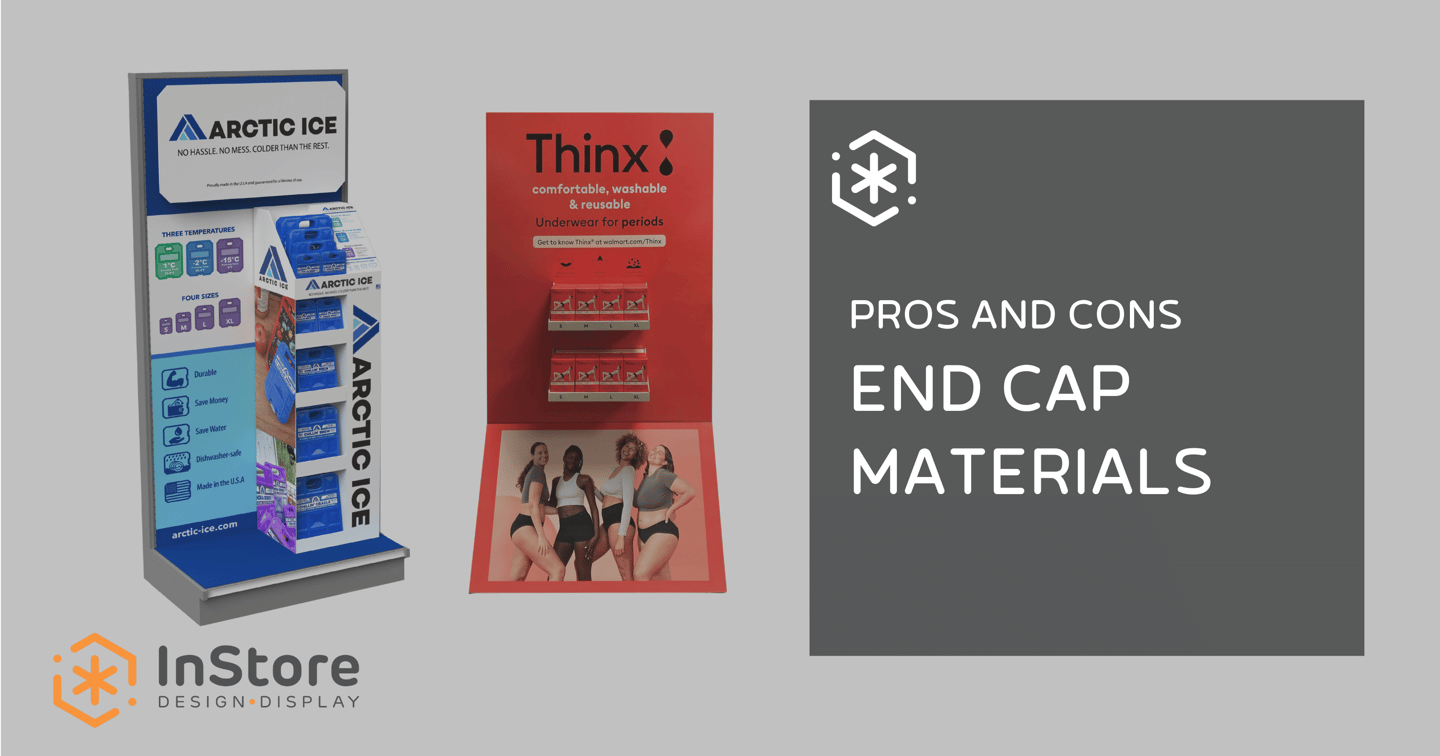

End Cap Display Material Trends 2024

End cap displays are a great way to showcase new products and promotions and catch the attention of customers while they are browsing retail stores. End caps allow your products to receive high visibility since they are positioned at the end of store aisles, which can ultimately lead to higher brand awareness and sales numbers. When designing a new end cap display for your product, it is imperative to consider the pros and cons of the various material options. Let’s explore what your company could consider when choosing the right end cap material.

Why is Choosing the Right End Cap Material Important?

End caps are an essential piece of a brand’s in-store marketing strategy. They allow a brand to get its product in front of potential customers to raise brand awareness and encourage impulse buys. There are a variety of materials that can be used for end cap displays depending on your goals. Whether you are looking for a display that is easy to construct, has significantly more durability, or just fits the vibe of your product best, we've got some tips on how to make the most of your end cap display.

Design

The design of your end cap display needs to emulate your brand and attract customers with eye-catching patterns and colors. Some end cap materials are significantly easier to design with than others. For example, corrugate easily conforms to different designs and shapes than other material, and it's a cost-effective although temporary choice. However, if you are looking for a higher end look that lasts longer, then a design with plastic, metal, wood or mixed materials may be the better way to go. Selecting a material to match your product’s design needs is essential to your brand’s in-store marketing strategy.

Durability

The lifespan of your end cap display is primarily determined by which material is used to construct it. While metal, wood, and plastics like acrylic, PVC, and PETG are more costly than corrugated cardboard, they are more durable materials, meaning you will not have to replace your in-store displays as often. Customers constantly pick up products from your display, put them back down, and deteriorate your display as its life progresses. If durability is your top priority, then you'll want to steer away from using corrugate as your material and consider wood, metal, or plastics like acrylic, PVC, and PETG.

Sustainability

Sustainability is a large priority for companies that work to maintain a positive brand perception. According to a recent study by NIQ (Nielsen IQ), 78% of consumers say sustainability is important to them. End caps can be created with recycled materials and can eventually be recycled when it is time to take them down. If your company wants to prioritize sustainability, utilize an eco-friendly material like corrugated cardboard with recycled content, PETG plastic, wood, or metal. If you would like to learn more about InStore Design Display’s capabilities with using eco-friendly materials, visit our Sustainability page!

What Are the Pros and Cons of Materials for End Cap Displays?

Corrugated Cardboard

Best for temporary displays, corrugated cardboard is made from three or more layers of kraft paper with the middle layer shaped in a ripple pattern to provide strength and structure. Corrugated cardboard provides more durability and strength than regular cardboard material.

|

Pros |

Cons |

|

✅ End caps that use corrugated cardboard can easily be constructed or broken down since the material is designed to easily slot together using materials like glue or tape. ✅ Corrugated cardboard is created with recycled content and can be recycled when it has completed its life cycle. ✅ This makes it a great candidate for companies that are looking for an eco-friendly material option. |

❌ Since corrugated cardboard is not as durable as other end cap material options, your display may have difficulty withstanding extreme pressure or moisture. ❌ The lifespan of your corrugated cardboard display may be significantly shorter than if acrylic, PVC, PETG, wood, or metal were used to build it. |

Plastic: Acrylic

Best for semi-permanent displays, acrylic is a type of plastic that is lightweight and a cost-effective substitute for glass that prioritizes showcasing your product over design. While acrylic is not the most commonly used material for end cap displays, it is important to consider it as part of your brand’s in-store marketing strategy.

|

Pros |

Cons |

|

✅ Acrylic is a stronger, lighter, and significantly more durable alternative to glass. ✅ Acrylic is difficult to break and easy to maintain, meaning it exceeds the lifespan of other end cap material options. |

❌ Acrylic can easily scratch, which can lower its attractiveness and design over time. ❌ While acrylic is recyclable, it requires specialized centers dedicated to acrylic recycling, making it more difficult to recycle than PVC and PETG plastics. |

Plastic: PVC

PVC (Polyvinyl Chloride) plastic is widely used for semi-permanent to permanent end cap displays due to its versatile properties and durability. It is a synthetic plastic polymer that is valued for its toughness, chemical resistance, and ease of use in manufacturing. PVC can be formed into various shapes and sizes, making it an ideal material for custom display designs.

|

Pros |

Cons |

|

✅ PVC plastic is highly durable, able to withstand significant wear and tear, and resistant to damage from impacts, making it suitable for long-term use. |

❌ While PVC is recyclable, the process is complex and not as widely accessible as other materials, potentially limiting its eco-friendliness. |

Plastic: PETG

PETG (Polyethylene Terephthalate Glycol) plastic is another excellent material choice for end cap displays, particularly when a clear, high-impact resistant option is needed. PETG is known for its clarity, strength, and ease of fabrication, making it a popular choice in retail environments for semi-permanent displays.

|

Pros |

Cons |

|

✅ PETG plastic offers excellent clarity and gloss, making it perfect for displays where product visibility is crucial. |

❌ PETG can scratch more easily than some other plastics, which may affect the visual appeal of the display over time. |

Wood

Wood is a popular choice for end cap displays that need to last for multiple years and for brands aiming to create a natural, rustic, or high-end aesthetic. It is a versatile material that can be stained, painted, or left in its natural state to match a brand's image.

|

Pros |

Cons |

| ✅ Wood offers a sturdy and durable structure, making it ideal for heavy or bulky products. ✅ It provides a high-end, natural appearance that can enhance the aesthetic appeal of the display and attract customers. ✅ Wood can be easily customized through carving, staining, painting, or other finishing techniques, allowing for a unique and branded look. ✅ Sustainable wood options, such as those certified by the Forest Stewardship Council (FSC), can align with eco-friendly brand initiatives. |

❌ Wood can be more expensive than other materials, especially if high-quality or specialty woods are used. ❌ It is susceptible to damage from moisture, pests, and changes in temperature, which can affect its longevity. ❌ Wooden displays are heavier and more challenging to transport and install compared to lighter materials like cardboard or plastic. |

Metal

Metal is often used for permanent or long-lasting end cap displays, especially in environments where strength and durability are paramount. Common metals used include aluminum, steel, and sometimes brass for a more decorative touch.

|

Pros |

Cons |

| ✅ Metal provides exceptional strength and durability, making it suitable for displays that need to support heavy products or withstand high traffic. ✅ It offers a sleek, modern look that can be easily integrated into various retail settings, from industrial to contemporary designs. ✅ Metal is highly resistant to damage from impacts, moisture, and temperature changes, ensuring a long-lasting display. ✅ It is recyclable, and many metals can be repeatedly recycled without degrading their properties, making it an environmentally friendly option. |

❌ Metal displays can be significantly heavier and more challenging to transport and set up compared to other materials. |

What Material is Best for your Brand's Display?

To choose the right material to build your end cap displays, consider each material’s design, durability, and sustainability as well as their pros and cons. Armed with this knowledge, you can better fit your product and budget to your display type and material choice.

Looking for a materials expert to guide your display design and build? Reach out and we'll get you set up with a consult.

About the Author

Quentin Vowells is InStore Design Display’s Plant Operations Manager. He oversees everything that goes into producing custom displays and getting them in-store—engineering, prototyping, manufacturing, fulfillment, kitting, shipping, and warehouse operations. He brings a discerning eye to the build part of our operation, and quality control is always on his mind. Connect with Quentin on LinkedIn where he regularly talks about #displayproduction, #designformanufacturing, #designengineering, and #qualitycontrol.

Subscribe Here

Stay up-to-date on what's happening on our podcast and blog.